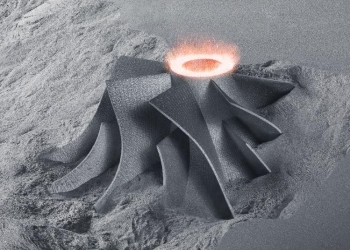

A team of researchers has developed a new titanium alloy that is strong and non-brittle under tension by combining alloy and 3D printing process design. This new research has the potential to expand the range of applications for titanium alloys, improve sustainability, and facilitate new alloy designs.

Their findings demonstrate the effectiveness of developing new, more durable, high-performance titanium alloys for use in aerospace, medical, chemical engineering, aerospace and energy sectors.

Titanium alloy is a high-performance material widely used in aerospace, medical, automotive and other fields. However, traditional titanium alloy production methods have limitations, such as long production cycles, high costs, and low material utilization rates. In recent years, with the development of 3D printing technology, the production methods of titanium alloys have also undergone revolutionary changes.

3D printing technology is a speedy prototyping technology based on digital model files, which creates three-dimensional entities by stacking materials layer by layer. In the production of titanium alloys, 3D printing technology can significantly improve production efficiency, reduce costs, improve material utilization, and achieve personalized customization.

Traditional titanium alloy production methods require complex forging and machining processes, long production cycles, and generate a large amount of waste. In contrast, 3D printing technology can quickly manufacture complex titanium alloy parts in a short time and has a high material utilization rate, which can reduce waste.

In addition, 3D printing technology can also achieve personalized customization. In traditional production methods, the shape and size of titanium alloy parts are limited, making it difficult to meet individual needs. 3D printing technology can customize titanium alloy parts of distinct shapes and sizes according to customer needs, improving products’ added value and market competitiveness.

The application of 3D printing technology in titanium alloy production has received widespread attention and application. Some advanced manufacturing companies have begun using 3D printing technology to produce titanium alloy parts, achieving significant economic and market benefits. Along with the continuous development and improvement of technology, 3D printing technology is expected to become the mainstream method of titanium alloy production and promote the development of related industries. Powder metal 3D printing technology has broad application prospects in many fields with unique advantages.

Titanium alloy powder 3D printing technology has a wide range of applications

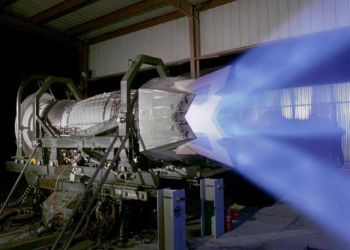

Aerospace: Because titanium alloys have the advantages of high specific strength, low thermal expansion coefficient, strong corrosion resistance, and good biocompatibility, they are widely used in the aerospace field. Through 3D printing technology, titanium alloy parts with complex structures, such as aircraft engine parts, fuselage structural parts, etc., can be manufactured.

Medical devices: Titanium alloys are also widely used in medical equipment, such as artificial joints, dental implants, etc. Through 3D printing technology, titanium alloy implants with personalized needs can be manufactured to improve medical effects.

Automobile industry: In the automobile industry, titanium alloys are mainly used to manufacture engine parts, suspension system parts, etc. Through 3D printing technology, these complex parts can be manufactured quickly and accurately, improving production efficiency.

Sporting goods: Titanium alloys are also extensively used in sporting equipment, such as golf clubs, bicycle frames, etc. Through 3D printing technology, high-performance titanium alloy sporting goods can be manufactured.

Other fields: In addition to the above fields, titanium alloy powder 3D printing technology is widely used in construction, jewellery, toys and other fields.

Supplier

Luoyang Tongrun Nanotechnology Co, Ltd., as a global chemical material purveyor and manufacturer with over 12 years of experience, is highly trusted for providing high-quality chemicals and nanomaterials such as graphite powder, zinc sulfide, nitride powder, calcium nitride, Ca3N2, 3D printing powder, concrete foaming agent, etc.

We usually transport our goods using DHL, TNT, UPS, and FedEx.You can choose T/T(USD), Western Union, Paypal, Credit card, Alipay or Alibaba trade insurance for payment. Please inquire if you want to buy a high-quality 3D printing powder; we will help.